Modern zoo architecture creates natural habitats

Africa Rocks in San Diego Zoo caters equally to the requirements of animals and visitors

Visiting Africa Rocks at San Diego Zoo is like going on a safari on foot. This is not a place where animals spend their lives in grey concrete landscapes behind metal bars. Here the new 68-million dollar complex has six different landscapes, from the Ethiopian Highlands through Madagascan forests to the coastal regions of South Africa, offering a completely new way of experiencing the biodiversity of Africa. The barrier-free view of the animals gives visitors the feeling that they are in the middle of a genuine habitat cleverly copied from its natural counterpart. This is all made possible by a barely perceptible delicate mesh construction which is the only separation between man and animal.

Paradigm shift in the relationship between man and animal

The exotic charm of wild animals has been attracting people to zoological gardens for more than 150 years. The reason for going to a zoo has not changed between then and now. What has changed though is the way people feel about the animals they are looking at. Whereas in former times the "wild creatures" used to be an object of curiosity, today they are seen as living beings who are to be treated sensitively and with respect.Animal conservation and preservation has become one of the major tasks zoos serve today. Zoos all over the world are respecting this change in the relationship between man and animal. Lots of zoos are commissioning new enclosures which, down to the very last detail, are created to reflect the natural habitat of the animals inside them. And visitors too benefit from this because modern enclosures are transforming zoos into an exciting world of adventure which not only lets us see lots of different animals but also gives us a glimpse of exotic landscapes live. Last but not least, sustainable zoo architecture is increasing the attractiveness of zoos.

And San Diego Zoo, which celebrated its centenary in 2016, is pleased about the constantly growing number of visitors coming through its gates. The powerful stainless steel mesh used in the Africa Rocks enclosure as both boundary and all-spanning roof mesh is predestined for the construction of enclosures which suit particular species and allow them to behave in a natural manner. X-TEND is the name of the mesh of stainless steel cables developed by Carl Stahl Architecture 28 years ago and optimized ever since to suit a range of applications in lightweight construction architecture. Meanwhile zoo enclosures are now one of the company's core competencies. And this is how in zoos all over the world – from Hanover to Tenerife and Sydney – natural-looking habitats have been created to suit individual species. And Carl Stahl Architecture, originally founded as a natural-fiber rope manufacturer, is responsible for everything from planning, through structural analysis to manufacture and on-site assembly.

Africa Rocks sets standards

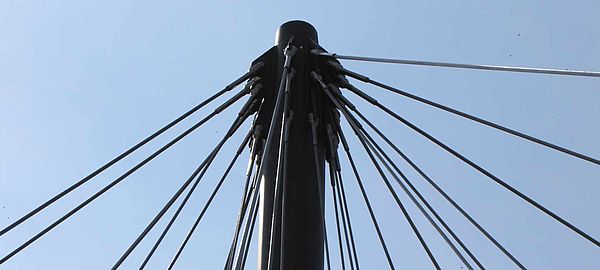

Elegant leopards, lemurs jumping from one tree top to the next, bustling meerkats, colorful birds and fossas that look like a curious mixture of dog, cat and mungo are the stars of Africa Rocks at San Diego Zoo. The only thing that separates them from the visitors is the graceful mesh of stainless steel cables from Carl Stahl Architecture. It is hardly noticeable but acts as a delimitation of the eight expansive enclosures and also spans the area as a transparent, organically shaped roof. The 6,500 square meters of roof mesh are borne by just nine inner supporting pylons with load-distribution rings – an impressive construction at its size and minimization and without doubt a milestone in modern zoo architecture.

The mesh may be virtually invisible, but its impact is great: Visitors are no longer just observers, shut out by thick metal bars or solid glass walls, but become part of the happenings as they stroll along the long, winding visitor's paths through the complex. The minimalistic architecture is also a major advantage for the principal performers themselves. The three-dimensionally pliable, flexible stainless steel mesh permits large spanning widths and enables the creation of spacious areas in which the animals can move freely and, importantly, up and down, too. This caters to the natural behavior of a large number of species as it permits climbing right up to the mesh roof.

Role model: spider's web

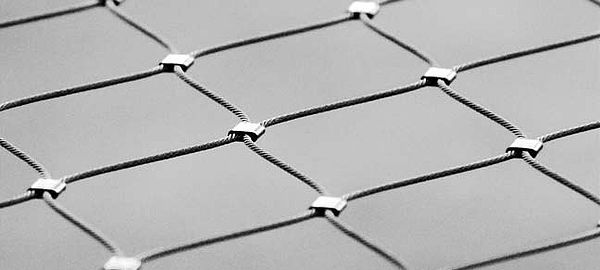

"Cable mesh constructions made of X-TEND can be stretched around enclosures and are thus ideally suited to modern zoo architecture," says project lead Vito Gualazzini from Carl Stahl Architecture. The 42-year-old civil engineer was involved in the Africa Rocks project from the very first talks with zoo management and architects more than three years ago to the final approval and hand-over of the operational enclosure to the customer. "They unite safety and aesthetics, are hard-wearing and durable, and offer virtually barrier-free insights and views thanks to their transparent structure," he explains. Quite appropriately, the planners based their ideas on nature: Like a spider's web, the area-covering structural element takes up the natural force path. The connection of sturdy stainless steel cables to a mesh of friction-pressed diamond shapes creates a special, flexible mesh structure which can take strong loads and offers a range of design possibilities. "Ultimately it is all about harmonizing the influential forces," explains Gualazzini. The lightweight formally minimized constructions have their own design language, which is always focused on the requirements of the particular species, topography, usability and appeal for the visitors.

Marlene Thimet, responsible for technical drafts for zoo architecture at Carl Stahl Architecture, explains: "Together with zoos and architects all over the world, we develop organically shaped mesh constructions, adapted down to the very last detail to suit individual requirements." And that is because both cable diameter and mesh width as well as the supporting and shape-giving elements, anchor span and method of attachment can be designed individually. "In the process we always take into consideration the demands of the everyday work and integrate inspection ports, sliding gates, trees and plants, climbing areas and places to sleep as well as of course entries and exits for the zookeepers," says Thimet who also designed the mesh supporting structure in San Diego. "The enclosures are the result of our extensive experience and careful technical planning, precise structural analysis and ultimately also know-how in terms of assembling on site." The successful planning and structural analysis of the complex are not just the work of special, state-of-the-art software programs. In fact Carl Stahl Architecture actually makes great use of classical architecture model construction. Marlene Thimet sees that as being particularly advantageous: "For me the model is both a draft that makes it possible for me to calculate the perfect mesh form, as well as a visualization aid for the customer. I have found that the people responsible at zoos can work better with a model they can see and touch, something they can walk around and view from different angles, because it gives them the perfect idea of the planned enclosure."

Existing trees skillfully integrated

For Carl Stahl Architecture, the San Diego Zoo project is the largest the company has realized to date worldwide. Around 17,000 square meters of mesh were implemented with a net material weight of around 6.5 tons. "The individual sections of the wall mesh are fastened to each other without any visible joints or additional vertical or horizontal cables," explains architect Wolfgang Betzler, Head of the Carl Stahl Architecture technical office."This means visitors have an unimpeded view into the compound on their way along the enclosures." The individual enclosures are integrated harmoniously into the topography which, together with the paths, bridges, rock formations and vegetation, presents a virtually natural habitat. The Acacia woodland biome, which houses leopards, meerkats and birds, features open grassy areas, wetlands and marsh plants. The Madagascar biome is home to honey badgers (ratels), fossas and lemurs and is dominated by pinnacle rock formations as well as alternating thorny woods and deciduous forests.

Carl Stahl Architecture faced very special challenges when it came to the landscaping because a large number of the valuable trees, which were taken out of the old compound dating back to the 1930s for the duration of construction, had to be replanted while the mesh was being erected. "A total of around 800 trees were planted in the whole complex, around 150 of which are under the mesh surface," says Wolfgang Betzler. "Since the trees can be anything up to eight meters high, it was not possible to replant them any later." And that meant precise coordination with the landscape gardeners. And the fact that among the plants there were some which were particularly worthy of protection, such as a well-established camel-thorn tree that birds had nested in for years and which under no circumstances should be damaged, did not make things any easier. At the northern end of the mesh construction the planners had to leave plenty of space around an old weeping fig with a crown diameter of more than 40 meters so the roof mesh would not hinder its growth.

Ingenious assembly technique

Depending on the particular species, the wall mesh of the individual enclosures has a mesh width from 25 to 50 millimeters, the main roof mesh of 100 millimeters. To stop any small rodents or birds getting into the enclosures from the top, Carl Stahl Architecture assembled a second mesh layer on the main roof mesh over every individual enclosure. "We developed this overlapping of the mesh area especially for the Africa Rocks project," says Wolfgang Betzler. And that meant the assembly engineers were faced with a special challenge: At great heights of up to 15 meters above the ground, they had to lay out the fine mesh, stretch it and fasten it to the edging cables on the main roof mesh from both a standingposition as well as on their knees. "To make sure the subsections were able to interlock smoothly during construction, we developed a special assembly technology for the project which considerably reduced the otherwise standard use of scaffolding and other assembly aids such as cranes and elevation platforms," says project lead Vito Gualazzini. "This was how we could ensure that for example the landscape gardeners could also carry out their work during the nine-month construction phase so that at the end of the day everything fit together."

Project: Africa Rocks, San Diego Zoo, USA

Architectural master plan: Miller Hull, San Diego, USA

Landscape gardening: ELM Ervin Lovett Miller, Seattle, USA

Supporting structure design, planning, statics, manufacture and assembly of the cable and mesh construction:

Carl Stahl ARC GmbH (with the collaboration of Marlene Thimet, Rudi Oswald), Suessen, Germany

Photos: Mike Torrey, San Diego

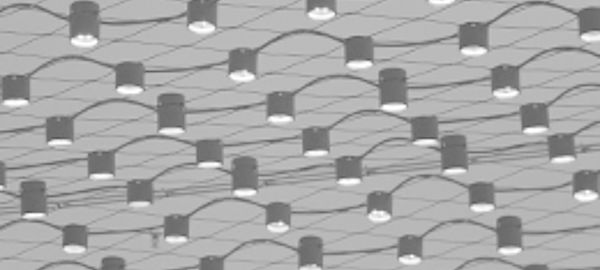

X-LED

X-LED

Balustrade infills

Balustrade infills

Safety

Safety

Façades

Façades

Greenery

Greenery

Suspension cable systems

Suspension cable systems

LED light design

LED light design

Zoo Enclosures

Zoo Enclosures

Fencing System

Fencing System

About us

About us

Career

Career

Locations

Locations